High-precision 3D scanning is used to create accurate part models, ensuring dimensional accuracy.

Complete engineering drawings are produced based on design requirements, with dimensions and tolerances clearly annotated.

Rapid prototyping of components to verify structural feasibility and design accuracy.

Precision-wound springs and aluminum-extruded trays are manufactured to ensure optimal elasticity and structural strength.

High-pressure forging increases metal density and enhances durability.

Precision CNC machining ensures dimensional accuracy and assembly fit.

Adjustable rod components are produced to provide precise suspension system tunability.

Components are machined for structural precision and long-term durability.

High-energy laser cutting ensures clean edges and improves production efficiency.

Professional welding techniques strengthen structural connections while maintaining uniform load distribution.

Surface anodization enhances corrosion resistance, wear resistance, and overall finish quality.

DU piston bushings are produced using injection molding, ensuring wear resistance and low friction performance.

A multi-functional machining center precisely processes the central axis, ensuring coaxiality and dimensional accuracy.

Material hardness is measured using a Rockwell hardness tester, ensuring metal strength and consistency.

Measures the concentricity of DU pistons, ensuring smooth operation and consistent lifespan.

Uses a 2.5D projector to inspect part dimensions and geometric accuracy.

Measures surface roughness to ensure optimal sliding performance and effective sealing.

Checks shaft coaxiality to prevent eccentricity from affecting structural load and operation.

Simulates harsh environments to assess corrosion resistance and ensure product durability.

Conducts dynamic testing of shock absorber damping curves to ensure stable performance and precise tuning.

High-precision 3D scanning is used to create accurate part models, ensuring dimensional accuracy.

Complete engineering drawings are produced based on design requirements, with dimensions and tolerances clearly annotated.

Finite Element Analysis (FEA) is performed using professional simulation software to evaluate product stress under various conditions, proactively identifying potential structural risks and ensuring strength and durability.

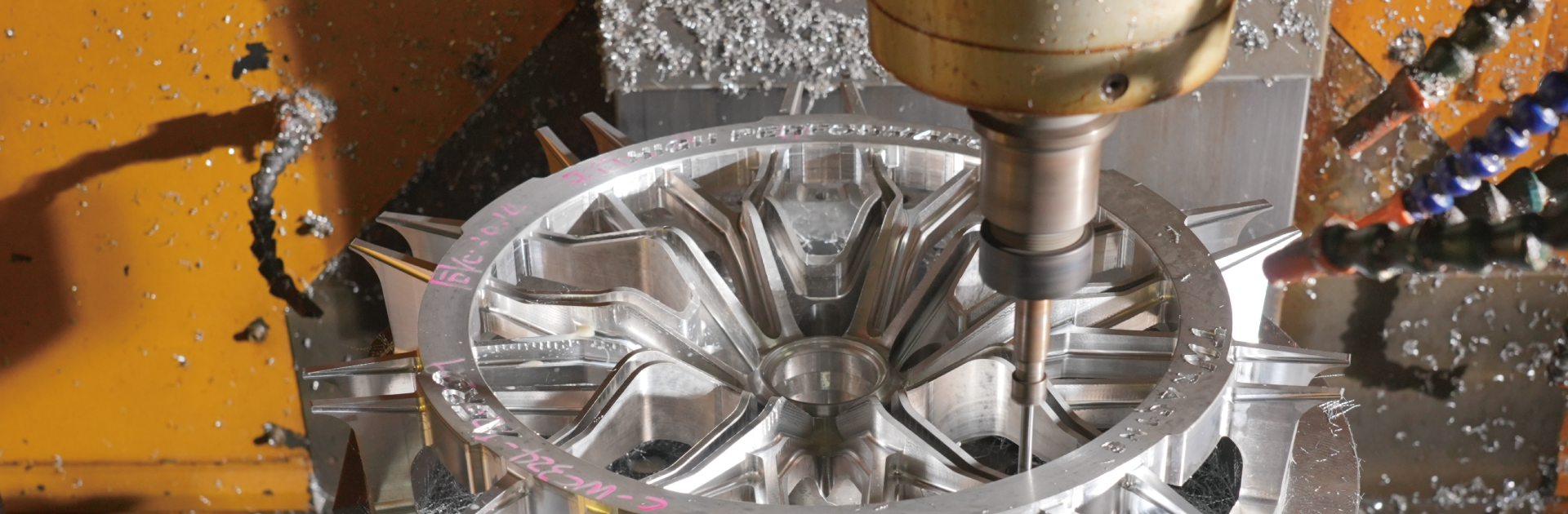

High-precision CNC milling is used for cutting, ensuring accuracy and stability in critical components, meeting strict manufacturing standards.

Products undergo surface grinding and polishing to enhance flatness and surface finish, providing a solid foundation for subsequent coatings and treatments.

Professional spraying and controlled baking processes ensure excellent adhesion, weather resistance, and aesthetic quality, with multiple color options available per customer requirements.

Simulates radial loads experienced during real-world use, conducting long-term durability testing to ensure the product maintains structural integrity under high-pressure conditions.

Evaluates material fatigue resistance through high-speed rotation and repeated bending, verifying the product can maintain safety and stability over extended use.

Simulates sudden impacts and extreme conditions to assess shock resistance, ensuring the product can reliably protect users in unexpected situations.

The Quality Management team performs rigorous inspections covering dimensions, appearance, and functionality. Products are assembled and securely packaged only after passing all standards, ensuring delivery in optimal condition.

High-precision 3D scanning is used to create accurate part models, ensuring dimensional accuracy.

Complete engineering drawings are produced based on design requirements, with dimensions and tolerances clearly annotated.

Precision parts machined with CNC lathes to ensure structural accuracy and concentricity.

Applies sandblasting to enhance surface adhesion and remove oxidation or burrs.

Professional spraying and controlled baking processes ensure excellent adhesion, weather resistance, and aesthetic quality, with multiple color options available per customer requirements.

Implements laser engraving or sticker application for brand identification and custom markings.

Performs dynamic balance testing to ensure stable disc rotation and minimize vibration at high speeds.

Assesses friction coefficient, wear resistance, and braking performance to guarantee safety and reliability.

Uses a projector to precisely measure O-ring dimensions and geometric accuracy, ensuring optimal sealing performance.

High-precision 3D scanning is used to create accurate part models, ensuring dimensional accuracy.

Complete engineering drawings are produced based on design requirements, with dimensions and tolerances clearly annotated.

Rapid prototyping to verify structural feasibility and design accuracy.

Manufactured using high-pressure forging to improve material strength and durability.

Precision CNC machining ensures dimensional accuracy and assembly fit.

Produces precision adjustment rods, ensuring the suspension system provides accurate adjustability.

Components are machined for structural precision and long-term durability.

High-energy laser cutting ensures clean edges and improves production efficiency

Professional welding techniques strengthen structural connections while maintaining uniform load distribution.

Surface anodization enhances corrosion resistance, wear resistance, and overall finish quality.

DU piston bushings are produced using injection molding, ensuring wear resistance and low friction performance.

Simulates pressurized conditions to detect air leaks, ensuring airtightness and pressure resistance.

Material hardness is measured using a Rockwell hardness tester, ensuring metal strength and consistency.

檢測材料硬度,確保結構強度符合標準。

Measures the concentricity of DU pistons, ensuring smooth operation and consistent lifespan.

Uses a 2.5D projector to inspect part dimensions and geometric accuracy.

Measures surface roughness to ensure optimal sliding performance and effective sealing.

Checks shaft coaxiality to prevent eccentricity from affecting structural load and operation.

Simulates harsh environments to assess corrosion resistance and ensure product durability.

Conducts dynamic testing of shock absorber damping curves to ensure stable performance and precise tuning.